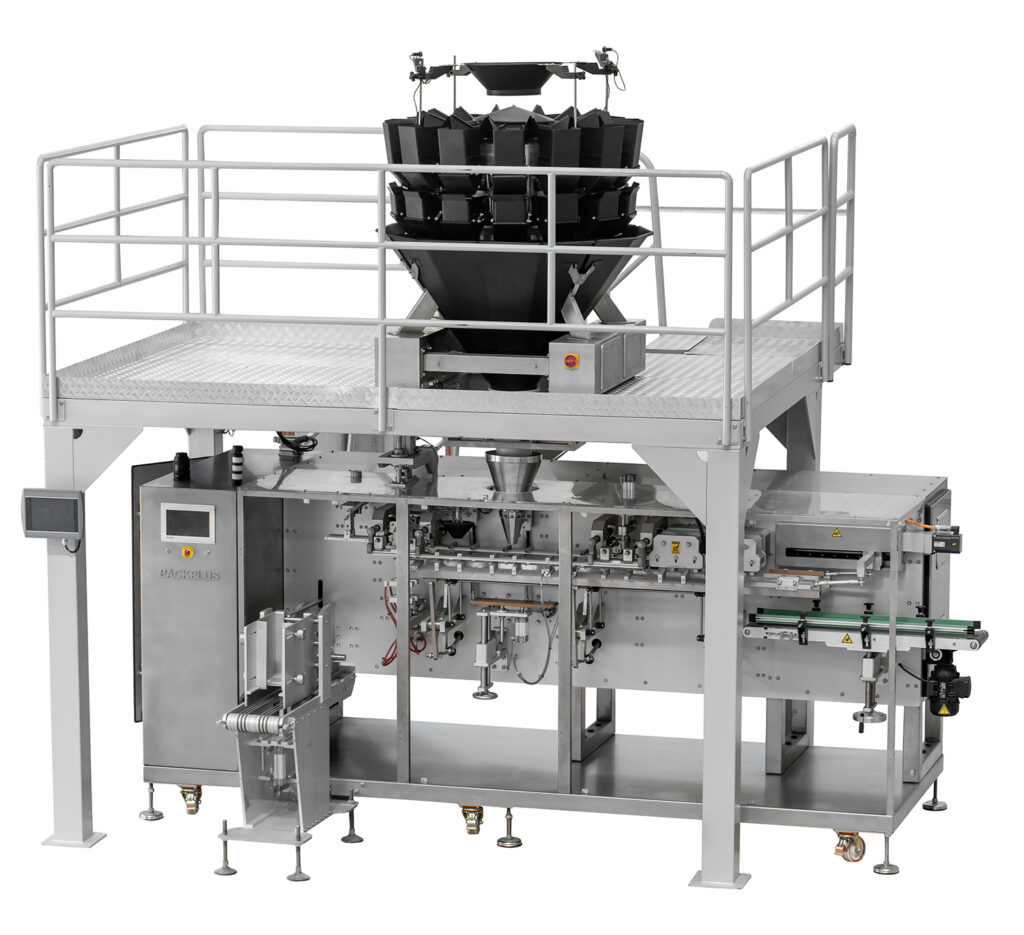

Flexible Packaging & Sealing Machines | Automated & Industrial Packaging Equipment

SEVVALUSA manufacturers packaging machines including vertical form fill seal, premade pouch fillers.

Simple, Efficient Packing Machines to Meet Your Needs

Packing machines are used in the food processing industry to package a variety of products, such as snacks, powders, liquids, and more. These machines are designed to form, fill and Seal pouches with food products and seal the pouches to create a final product that is ready for packaging and distribution.

Thinking of making a major investment in automated packaging equipment? Why not talk to our experts first so they can help you decide on the types of equipment that will work best for your application? Click to reach us

There are several benefits to using packaging machinery in the manufacturing process. Some of these benefits include:

-

Efficiency: Pre-made pouch packing machines are designed to be efficient and accurate, which can help to reduce the labor costs associated with manual packaging. They can also be used to add an extra level of automation to the process of packaging and sealing, which can help to improve the efficiency and output of the food processing business.

-

Flexibility: Pre-made pouch packing machines can be used to package a variety of products and can be customized to meet the specific needs of the food processing business.

-

Barrier protection: Pre-made pouch packing machines can provide a barrier protection for the food products, which can extend the shelf life of the products and help to maintain the freshness and quality of the food products.

-

Branding and marketing: Pre-made pouch packing machines can print and apply labels, and product information, which can help to market and promote the food products.

-

Cost-effective: Pre-made pouch packing machines can be cost-effective solution for packaging food products, as it eliminates the need for additional packaging materials such as cans, bottles, and cartons.

Overall, pre-made pouch packing machines are an important tool in the food processing industry, as they can help to improve efficiency, flexibility, barrier protection, branding, cost-effective and also help to maintain the freshness and quality of the food products.