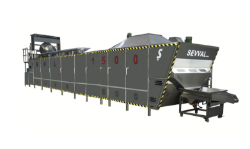

The Best Compact Roasting Line for Nut Processing Companies

Continuous Nut Roaster

The best compact roasting line for nut processing companies. Roasters are designed to process all kind of nuts and seeds in single line 3 in 1. It give flexibility to produce salted nuts, plain roasted nuts or flavored nuts.

Lowest operational cost which can be run only 1 person. By data logging system, Parameters always monitoring and recording.

provides maximum fuel efficiency with the lowest possible operating cost. These ovens are chosen by food processors throughout the world when roasting or drying peanuts, almonds, hazelnuts, sunflower seeds or other similar materials

Our company specializes in providing top-of-the-line dry roasting equipment for a variety of seeds and nuts, including sunflower seeds (both inshell and kernel), peanuts, almonds, cashews, pistachios, hazelnuts, pecans, chickpeas, and pumpkin seeds (papitas). We understand that every roaster has unique needs, which is why we offer a range of models to meet the demands of small artisanal roasters, as well as large commercial operations. Our four models, the SVL2000, SVL1500, SVL250, SVL500, and SVL1000, are designed to roast different quantities of seeds and nuts, ensuring maximum efficiency and productivity. Each model comes with its own unique capabilities and is tailored to roast different quantities of seeds and nuts, making it easy to find the perfect fit for your operation. Upgrade your roasting process and improve your production with our dry roasting equipment today.

Project Management

We engineer customized processing solutions that focus on best flow helping you lower operational cost and more flexibility to reach your production goals.

Dry roasting ovens are a great option for those who are in the business of roasting seeds and nuts. They offer many benefits that make them efficient and cost-effective for roasters.

One of the main benefits of using a dry roasting oven is the ability to roast large quantities of seeds and nuts at a time, which increases productivity and reduces overall roasting time. Additionally, these ovens are designed to evenly roast the seeds and nuts, ensuring a consistent and high-quality final product. This is achieved by precise temperature controls that allow for fine-tuning of the roast.

Operating a dry roasting oven is also relatively straightforward, making it easy for anyone to use. The controls are user-friendly and allow for adjustments to the temperature, making it easy to achieve the perfect roast.

In summary, dry roasting ovens offer a range of benefits that make them an efficient, cost-effective, and user-friendly option for roasters. Our five models, SVL2000, SVL1500, SVL250, SVL500, and SVL1000, are designed to meet the needs of different customers, providing a range of capabilities to suit different roasting needs.

SevvalUSA new series of processing profiles indicates nut roasters can achieve an log kill reduction using continuous monitoring with a control system. Data-modeling protocols developed and validated for the nut industry demonstrate applications in grain-based ready-to-eat products such as nuts snacks and breakfast cereals. Demonstrate controllable operating conditions which will deliver a minimum required log-reduction of target microorganism, Throughput (belt/chain speed; bed depth); air temperature; air flow; incoming nut temperature & moisture; cooling flow & temperature.

Continuous Multi-Zone Convection System

Overview

A continuous multi-zone convection system is engineered to provide efficient drying and roasting of food products in a controlled, gentle, and sanitary manner. This system ensures first-in, first-out production, guaranteeing even treatment of all products.

Key Features

Multi-Zone Design:

- Independent Zones: Each zone can be controlled independently for temperature, airflow, and humidity. This allows for precise adjustments to meet the specific drying or roasting requirements of different products.

- Optimized Heat Distribution: Ensures consistent product quality by providing uniform heat distribution across all zones.

Continuous Operation:

- First-In, First-Out (FIFO): Guarantees that products are processed in the order they enter the system, ensuring even treatment and consistent quality.

- Reduced Handling: Continuous conveyance minimizes the need for manual handling, reducing contamination risk and labor costs.

Gentle Processing:

- Adjustable Airflow: Customizable airflow speeds to gently process delicate products without causing damage.

- Variable Temperature Control: Precise control over temperature settings to prevent overheating and ensure optimal product quality.

Sanitary Design:

- Hygienic Construction: Made from food-grade materials that are easy to clean and maintain.

- CIP (Clean-In-Place) Systems: Automated cleaning systems that ensure thorough sanitation between production runs, reducing downtime and contamination risks.

Energy Efficiency:

- Heat Recovery Systems: Capture and reuse waste heat to improve energy efficiency and reduce operating costs.

- Insulated Chambers: Minimize heat loss, ensuring energy is used effectively.

Advanced Control Systems:

- Automated Monitoring: Real-time monitoring of critical parameters like temperature, humidity, and airflow, allowing for automatic adjustments to maintain optimal conditions.

- Data Logging: Records operational data for traceability, quality control, and process optimization.

Versatility:

- Wide Range of Products: Suitable for various food products, including nuts, seeds, grains, and other items that require precise drying or roasting.

- Scalability: Can be customized to different production capacities, from small-scale to large industrial operations.

Benefits

- Consistent Product Quality: Ensures uniform drying and roasting, resulting in consistent product quality.

- Improved Safety and Hygiene: Reduces contamination risks through automated handling and cleaning processes.

- Operational Efficiency: Continuous operation with FIFO processing improves throughput and reduces production bottlenecks.

- Energy Savings: Energy-efficient design lowers operational costs.

- Customizability: Ability to adjust parameters for different products and production needs.

Applications

- Food Processing Industry: Drying and roasting of nuts, seeds, coffee beans, cereals, and snack foods.

- Pharmaceuticals: Drying of ingredients where gentle and sanitary processing is crucial.

- Agriculture: Processing of grains and other agricultural products requiring moisture control.

This advanced multi-zone convection system is designed to meet the rigorous demands of modern food processing, offering flexibility, efficiency, and high standards of hygiene.