SVL1000 Compact Nut Roaster

The continuous roaster SVL1000 is one of the best nut roasters due to its advanced roasting system. The system is based on heat and features one-layer belts. Nut roasting systems are crucial for achieving great results, and the SVL1000 provides flexibility in roasting a variety of nuts and seeds, including sunflower seeds, hazelnuts, pistachios, peanuts, cashews, almonds, pumpkin seeds, and more. Unique roasting, great results, roasted nuts—a modern roasting line for all kinds of nuts and seeds.

Features:

User-friendly

Superior performance

High energy efficiency

Accessible design for maintenance and cleaning

Simple cleaning process (belt washing and dry brushing)

Low thermal loss and minimal operating expenses

Built-in cooling system

Optimized design

Capacity/hr

2000-4000 lbs/hr

Consumption

~1.600.000 BTU

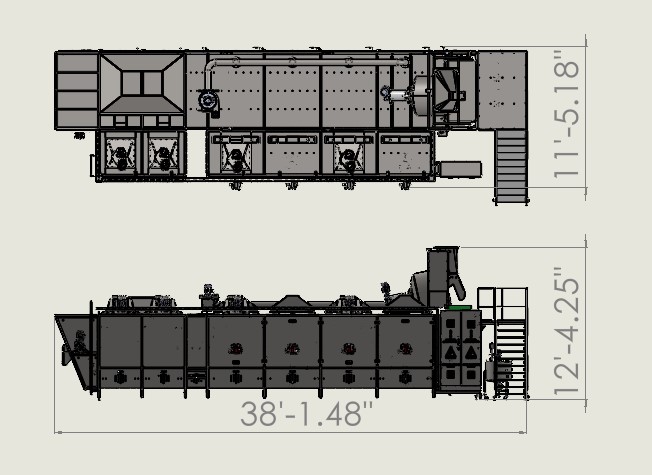

Dimensions

39'x12'x12'

Power

Single Phase, 110-220-230V, 20A, 50-60Hz 40 Amps

Heating

Propane, Natural Gas 1/2'' NPT BTU Gas Supply Pressures min 5''x max7''wc

Space Requirment

Blueprint for layout

Data Logging

Fan Speed, Conveyor Speed, Damper settings/Airflow, Product bed depth

Connection

Compatibility with Third party Software

- Salted Sunflower Seeds 800-1000 kg/hour 1600-2200 lbs

- Salted Peanuts 1000-1400 kg/hour 2300-3080 lbs

- Peanut in Shell 350-450 kg/hour 745-990 lbs

- Salted Chickpeas 1125-1500 kg/hour 2480-3300 lbs

- Almonds 1125-1500 kg/hour 2480-3300 lbs

- Cashew Nuts 1125-1500 kg/hour 2480-3300 lbs

- Hazelnuts 1875-2500 kg/hour 4130-5510 lbs

- Pumpkin Seeds 800-1000 kg/hour 1600-2200 lbs

- Pistachio 1125-1500 kg/hour 2480-3300 lbs

- Total Electric Power 37,07 kW

- Maximum Thermal Power 320 kW

- Average Gas Consumption 18-36 Nm³/h

- Average LPG Consumption 14-30 kg/h

- Average Diesel Consumption 18-26,8 lt/h

Heat Insulation

The heat in the combustion chamber is very well circulated and used efficiently during roasting. As a result, the heat in the hood is always less than the heat in the burner.

SVL1000 – ROASTING OVENS Heat Insulation.Adjustable Humidity Decrease

Each chamber has humidity decrease adjustments, allowing the humidity to be reduced to the desired amount from the desired chambers.

SVL1000 – ROASTING OVENS Adjustable Humidity Decrease.Belt Cleaning

This function ensures constant cleaning of the belt for new products.

SVL1000 – ROASTING OVENS Belt Cleaning.Product Thickness Adjustment

Using the adjustment arm and window, you can adjust the thickness of the product on the belt.

SVL1000 – ROASTING OVENS Product Thickness Adjustment.Washing

Before roasting each product, hygienic cleaning is done using the mobile cleaning option.

SVL1000 – ROASTING OVENS Washing.Product Discharge System

This special design minimizes damage to the roasted product and also sieves the dust.

SVL1000 – ROASTING OVENS Product Discharge System.Heat Circulation System

A 90% efficiency is provided with the special design of the combustion system.

SVL1000 – ROASTING OVENS Heat Circulation System.Specially Designed Reducer

Problem-free usage is ensured by means of steel gears.

SVL1000 – ROASTING OVENS Specially Designed Reducer.

Technology in a Single Key

Operating our nuts roasting machines is simple, thanks to user-friendly touch screen panels. Optional software features include end-of-day production and operator reporting. Maintenance is made easier with online PLC connections.

Optional Solutions…

All software programs are developed by SevvalUSA engineers. Custom additions can be made to meet the specific needs of our customers.