Automatic Pre-Made Pouch Packing Machine Plus Pro Single

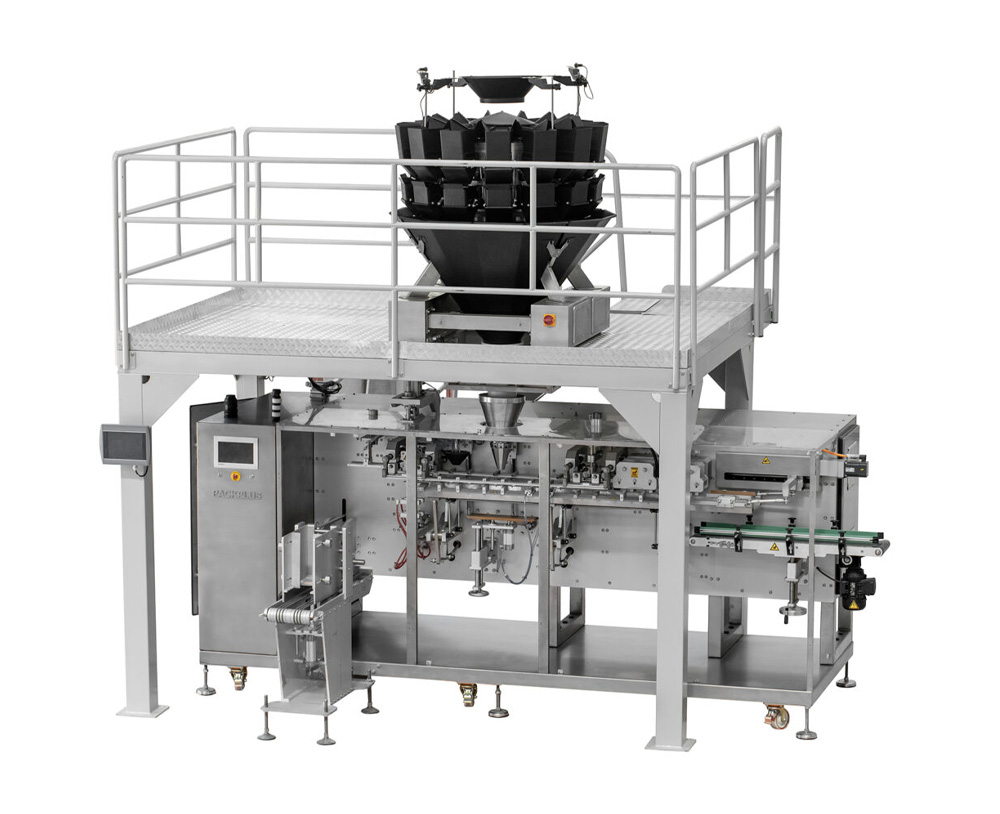

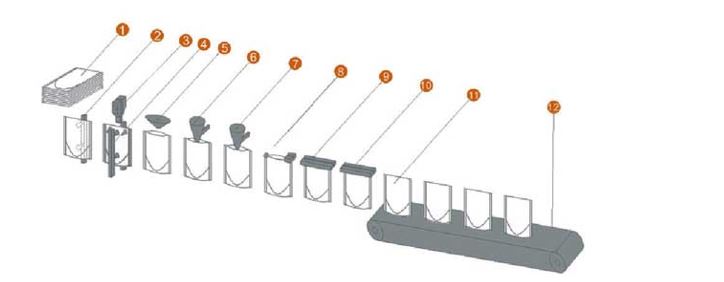

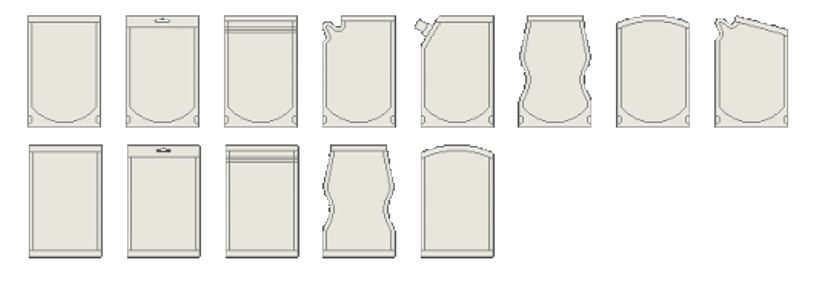

The automatic packing pre-made pouch packaging machines Single pro Series are designed for automatically opening, filling, sealing pre-made pouches, which can operate on variety of bag styles, including spouted pouches, 3 or 4 side sealed, pillow pouches, stand up bags, gusseted pouches, quad sealed and box pouches with zipper or not. Designed for a variety of industries and for Nuts, coffee, pasta, cereals, pet foods and liquid products, this equipment includes features that exceed product  requirements.

requirements.

- Flexibility for a wide

variety of bag styles and ranges - Quick changeovers

- Fast-acting, & reliable.

Up to 50 Pouches per min

More Models

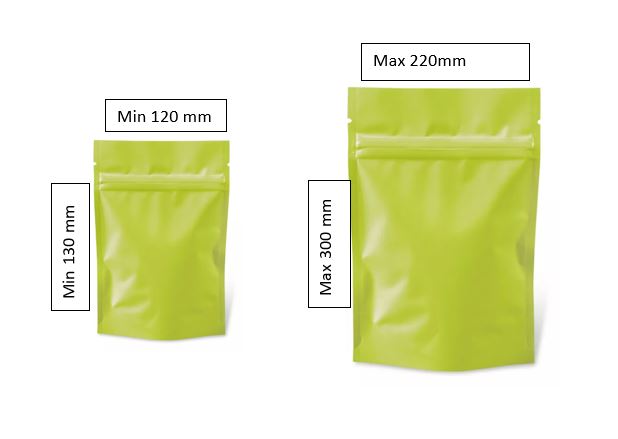

Pouch Size

Width 120 – 220 MM Length130 – 300 MM

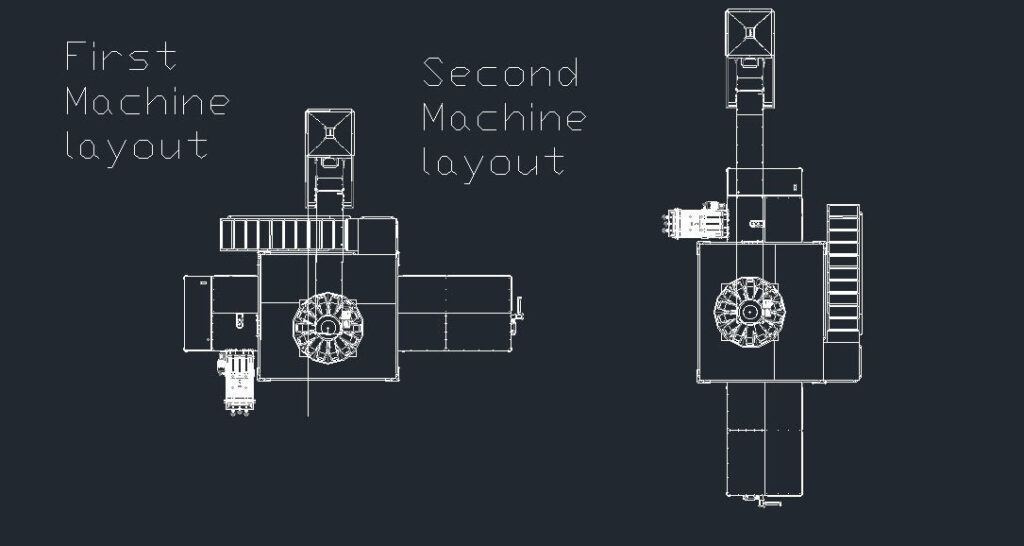

Flow

Flow Direction

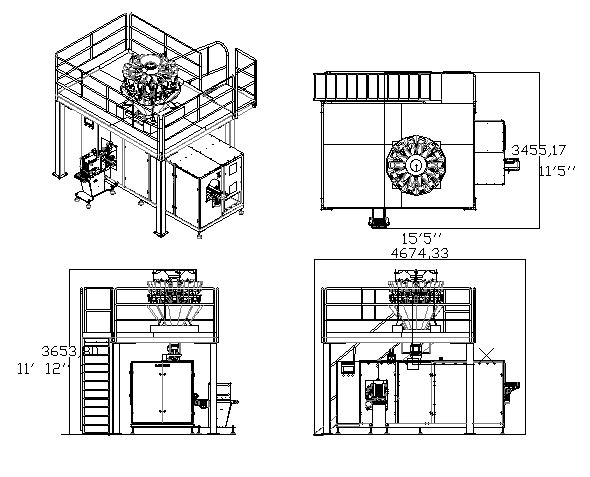

Dimensions

15'x13'x 20'

6000 lbs

Servo Control

Single Phase, 110-220-230V, 20A, 50-60Hz

PLC

HMI System Motion Control

Servo Control

Servo Control 12-24 pcs

Data Logging

Easy to change recipe by Servo components. eTrack

Connection

Removed Access

Automatic Pre-Made Pouch Packing Machine Plus Pro Single

PRE-MADE POUCH FIL AND SEAL PACKING MACHINE SPECIFICATIONS

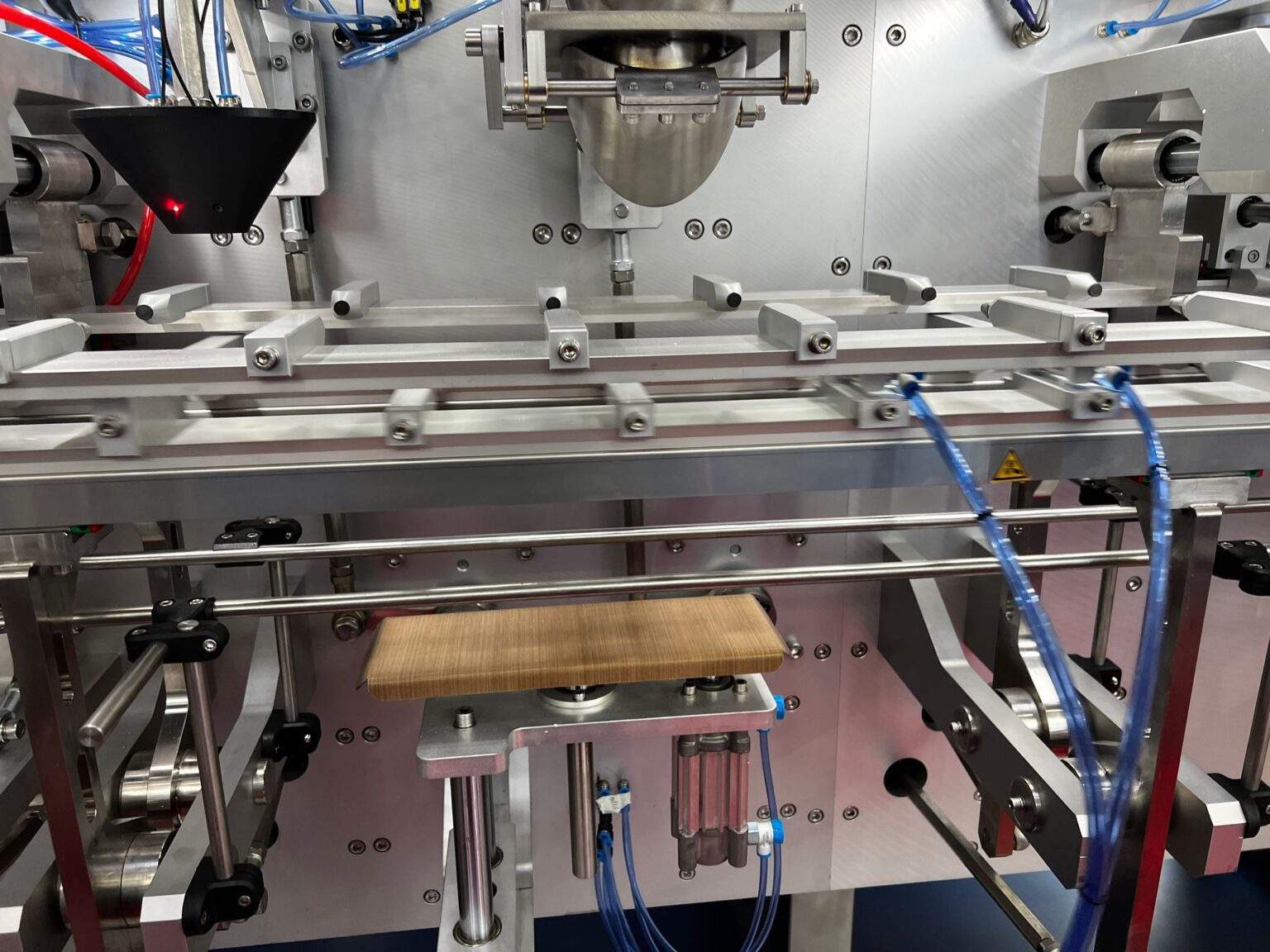

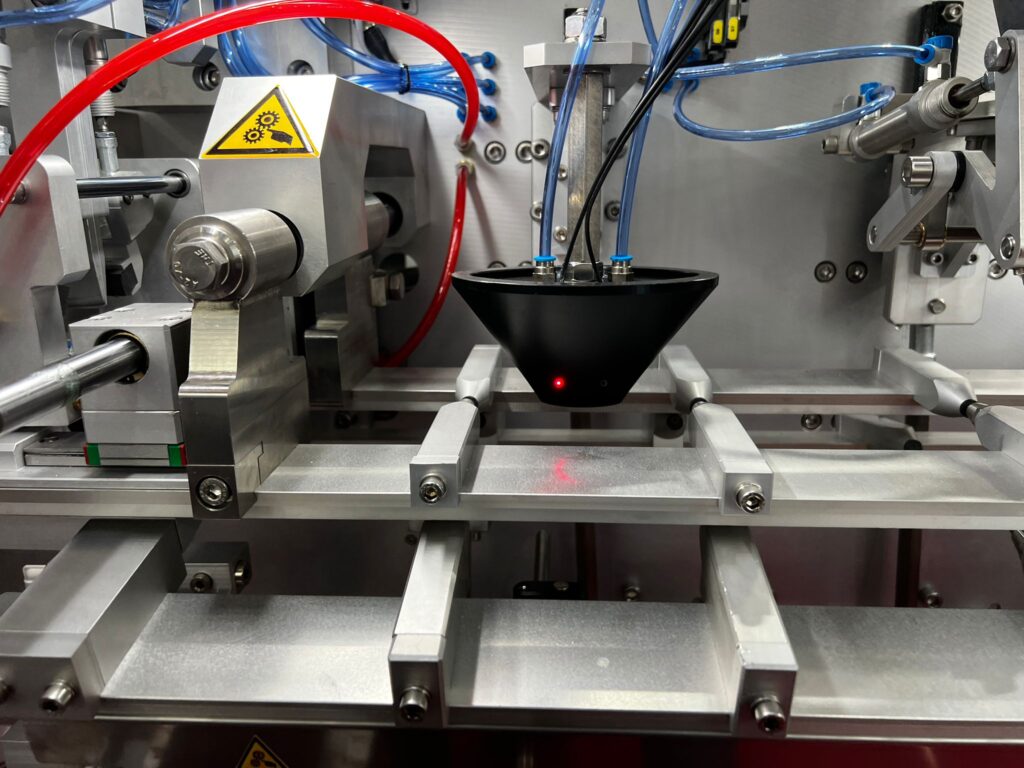

- PLC – HMI System Motion Control – SERVO Control 12 – 18 Pcs base on options-High Capacity Vacuum Pump Pouch Opening

- Easy to change receipe by Servo components-Speed 40 – 50 Pcs/min-Pouch Width 90 – 160 MM ( 3.6 ‘’ – 6.3’’ )

- Pouch Lenght – 320 MM ( 12.6‘’ )-Weight of machine 2500 – 3000 KG-Body Steinless Stell 304-Good for food Grade

- Pouch opening by vacuum pump-No bag or no open no fill function-All body parts are made 304 of stainless Steel (#304).

- Bag in feed system-Pouch Indexing easy set up-Pouch is precisely indexed-Seal Area of the pouch is air blasted to remove dust

- Pouch is Securely sealed with hot bar

TYPES OF POUCHES

Stand-up pouches – Flat pouches – Spouted pouches – Retort pouches – Zipper pouches – Shaped pouches

1-Flexible plastic films: Plastic films are widely used for pouch packaging due to their versatility, durability, and barrier properties. Common types of plastic films include:

- Polyethylene (PE): PE films are lightweight and have good moisture resistance. They are commonly used for packaging products like snacks, frozen food, and produce.

- Polypropylene (PP): PP films offer excellent clarity and heat resistance. They are commonly used for packaging products like confectionery, snacks, and baked goods.

- Polyethylene terephthalate (PET): PET films have excellent strength, clarity, and gas barrier properties. They are commonly used for packaging products like beverages, sauces, and personal care items.

- Nylon (PA): Nylon films have high puncture resistance and are commonly used in applications where strength and durability are critical, such as packaging meat and cheese.

2-Aluminum foil: Aluminum foil is used as a barrier layer in pouches to provide excellent protection against oxygen, light, and moisture. It is commonly used for packaging products that require high barrier properties, such as coffee, snacks, and pharmaceuticals.

3-Laminated films: Laminated films are composed of multiple layers of different materials, combining their respective properties. For example, a common structure is a combination of plastic film and aluminum foil, which provides both barrier properties and flexibility. Laminated films are used for various products, including food, beverages, and personal care items.

4-Paperboard: Paperboard pouches offer a more sustainable and eco-friendly option compared to purely plastic-based pouches. They are commonly used for packaging products like cereals, powders, and dry goods.

TECHNICAL SPECIFICATIONS

Power | Kw | 15,0 |

Voltage | V | 480 (3 phase+N+G) |

Maximum Voltage changes Ratio % | % | ± 5 |

Power Frequency | Hz | 50 |

Working Room Temp | °C | +5 to +40 |

Mouister | <80% | |

Loud Level | dB | < 80 |

Electircal Panel Safety | IP54 | |

Min. Machine Safety | IP21 | |

Pressure | bar | 8 to 10 |

Air Consumption | m3/m | 50 |