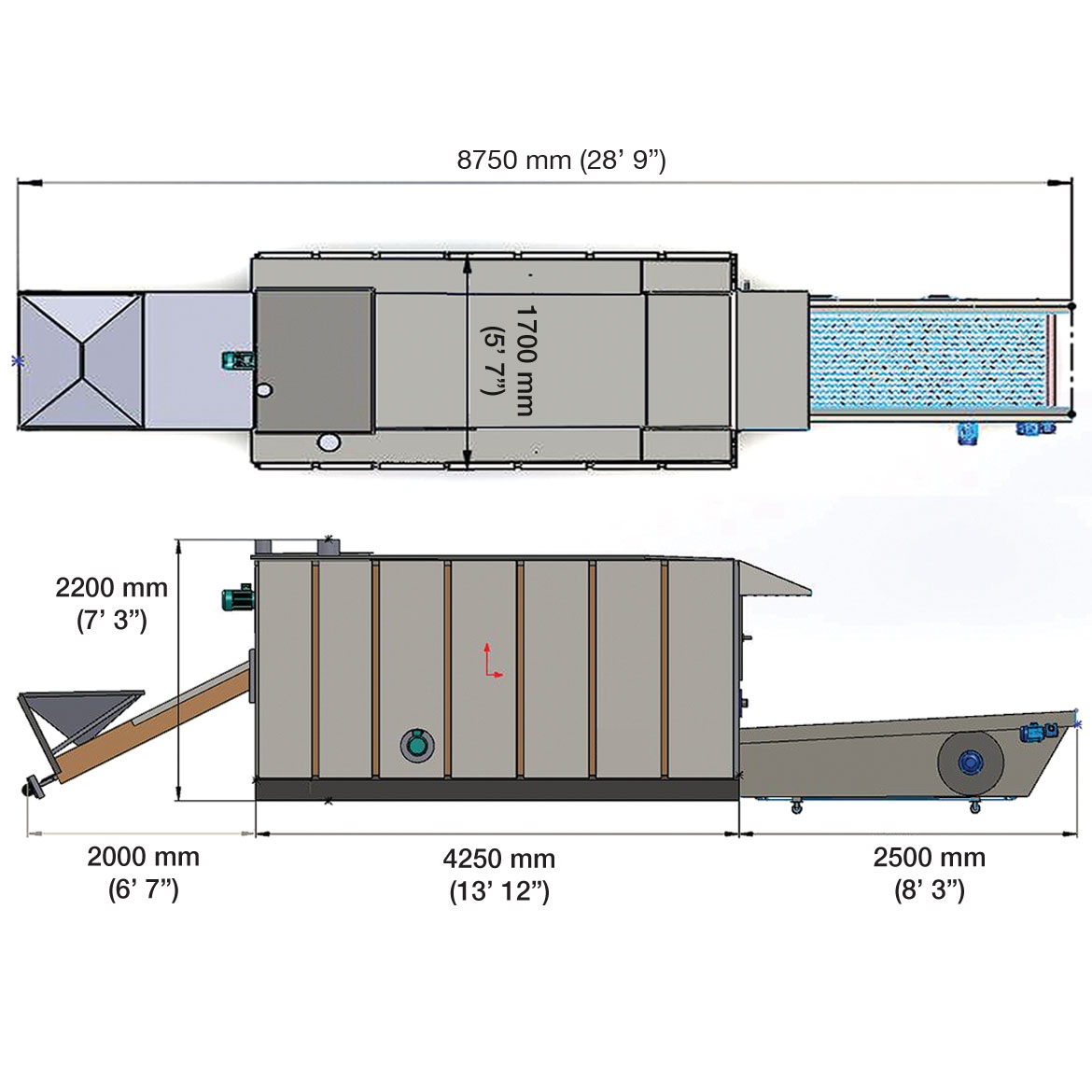

SRX60 ROASTING OVENS

Moisture and gas exhaust..

Precision temperature

measurement..

Tasty roasting..

User Friendly touch control

Easy product feed

Natural roasting in 25 meters, as if it's roasted in wooden oven, long shelf life...

- Salted Sunflower Seeds 100-125 kg/hour 220-275 lbs

- Salted Peanuts 150-190 kg/hour 330-418 lbs

- Yellow Pumpin Seeds 100-125 kg/hour 220-275 lbs

- Salted Chickpeas 165-215 kg/hour 363-606 lbs

- Unsalted Peanuts 140-180 kg/hour 308-396 lbs

- Almonds 150-190 kg/hour 330-418 lbs

- Cashew 137-175 kg/hour 297-385 lbs

- Hazelnuts 175-230 kg/hour 385-506 lbs

- Pistachio 150-190 kg/hour 330-418 lbs

- Total Electric Power 4,82 kW

- Maximum Thermal Power 100 kW

- Average Gas Consumption 4,5-12 Nm³/h

- Average LPG Consumption 3,5-9 kg/h

- Average Diesel Consumption 4,5-6,7 lt/h

- 800 °C resistant isolation.

maximum energy saving by minimizing heat loss by heat insulation capacity 800 degree celcius - Chimney and vapor exit.

Heat created at combustion chamber is well circulated inside the oven and this heat roasted the products. This way the chimney heat is always less then the burner - Cencors.

Enhancing employee safety sensors. - Hood.

The hot air and humidity that comes out from the roasted product at the stage of cooling, is absorbed by the hood - Good insulation.

Energy which run inside the machine is used without loss. - Heat circulation system.

90% efficiency is provided with the special design of combustion system - Five layer belt system.

Products more tasty by slow roasting and cooling in five layer belt system - Air curtains.

Best isolation method with air curtains for maximum energy efficiency - Easy cleaning.

By door, easy cleaning possibility - Strong wheels.

Assembling and operating is easier by means of rubber wheels unharming the floor

Technology in a single key

Nuts Roasting Machines operation is quite easy with friendly touch screen panels. End of the day production and operator reporting can be added in software optionally. Maintance is more easy with online connection to PLC

Optional Solutions…

All software programs are written bu Sevval Makine engineers. According to special needs of the customeri, additionals can be done.

Conveyor Roaster: SRX serias roasters have 5 layer belt and with keeping same aroma of nuts and seeds while roasting.

Is Salting Automatic?

With automatic salting, without depending on the standart capasity production of man power, the product is easily and undamaged salted.

Is Salting Manual?

The salting process is done without damage to the product and loss of space in production line

Roasted Products to Sags or Silo?

For minimum time loss and maximum production volume, automated elevator and silo solutions

Do you want to make final check?

You can make final check of your products at ergonomic and hygenic automated selection belt systems