HB Batch Roasters series

HB Batch Traditional Roasters is a specialized roaster that is designed to roast nuts with salt. It features a special basket that is used to remove the roasted products and the salt. This allows for easy separation of the roasted nuts and the salt, making it a convenient option for those who regularly roast nuts with salt.

High capacity homogeny roasting system.

HB Batch Roasting Ovens are specialized ovens that are designed to roast a variety of different types of seeds and nuts, including watermelon seeds, coated nuts, pistachios, sunflower seeds, yellow pumpkin seeds, and black sunflower seeds. These ovens are unique in that they are capable of roasting these products in salt, which is said to enhance the flavor and appearance of the finished product. The ovens are produce more shiny, visually appealing products.

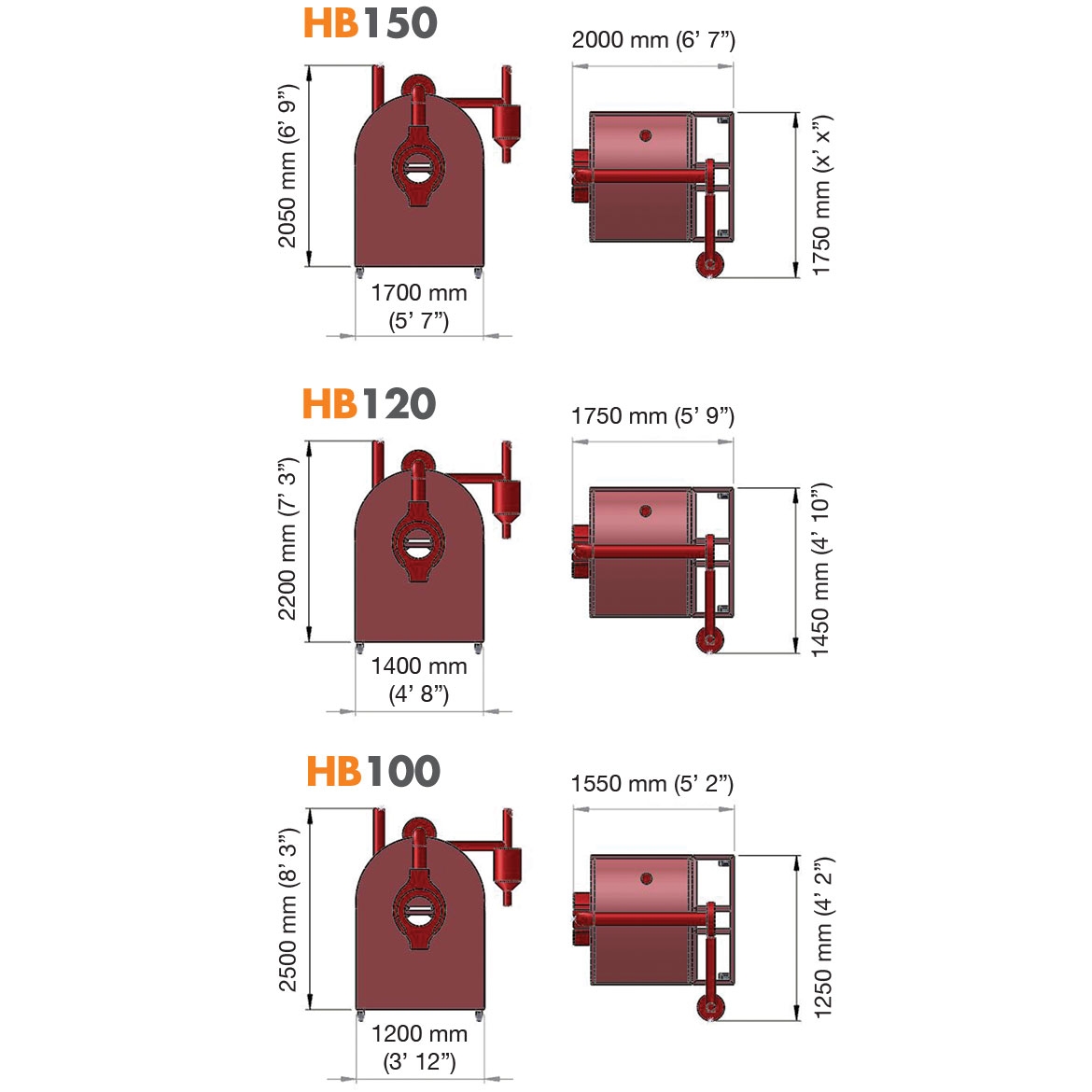

- HB 100 125 kg/hour 275 lbs

- HB 120 150 kg/hour 330 lbs

- HB 150 200 kg/hour 440 lbs

- Total Electric Power 2,33 kW

- Maximum Thermal Power 80 kWAverage Gas Consumption 3,6-5 Nm³/hAverage LPG Consumption 2,5-5 kg/hAverage Diesel Consumption 3,57-6,7 lt/h

- Total Electric Power 2,75 kW

- Maximum Thermal Power 100 kW

- Average Gas Consumption 4,5-12 Nm³/h

- Average LPG Consumption 3,5-9 kg/h

- Average Diesel Consumption 3,57-6,7 lt/h

- Sample Spoon.

You can control the roasted product with the sample spoon - Cleaning.

Proper machine cleaning can be done by auxiliary drawers - Heat Control.

The heat in the burner, air heat in chambers and product heat can be controlled by this unique design. - Piston.

Capability of fast discharge without manpower need. - Twister arm.

Sensetive sieving and long term use of the sieve with the teister arm adjustment. - Heat circulation system.

90% efficiency is provided with the special design of combustion system - Sieve.

Special design, to cool and seperate the salt from the roasted product. - Product discharge.

With this folding lid, product discharge has never been so easy.

Technology in a single key

Nuts Roasting Machines operation is quite easy with friendly touch screen panels. End of the day production and operator reporting can be added in software optionally. Maintance is more easy with online connection to PLC

Optional Solutions…

All software programs are written bu Sevval Makine engineers. According to special needs of the customeri, additionals can be done.