EB Batch Roasting series

A direct flame batch roaster has the heat source located within the roasting chamber and the product is roasted directly over the flame. This method of roasting can produce intense heat and can result in a more evenly roasted product, but it also requires more skill and attention to ensure that the product does not burn.

High capacity homogeny roasting system.

EB500 is a type of Batch Roasting Oven which roasting the hazelnut in shell, peanut in shell, pumpkin seeds, sunflower seeds, melon seeds, almond in shell, pistachio, almond, peanut. Roast in salt; first in the world and more shiny products with new generation roasters.

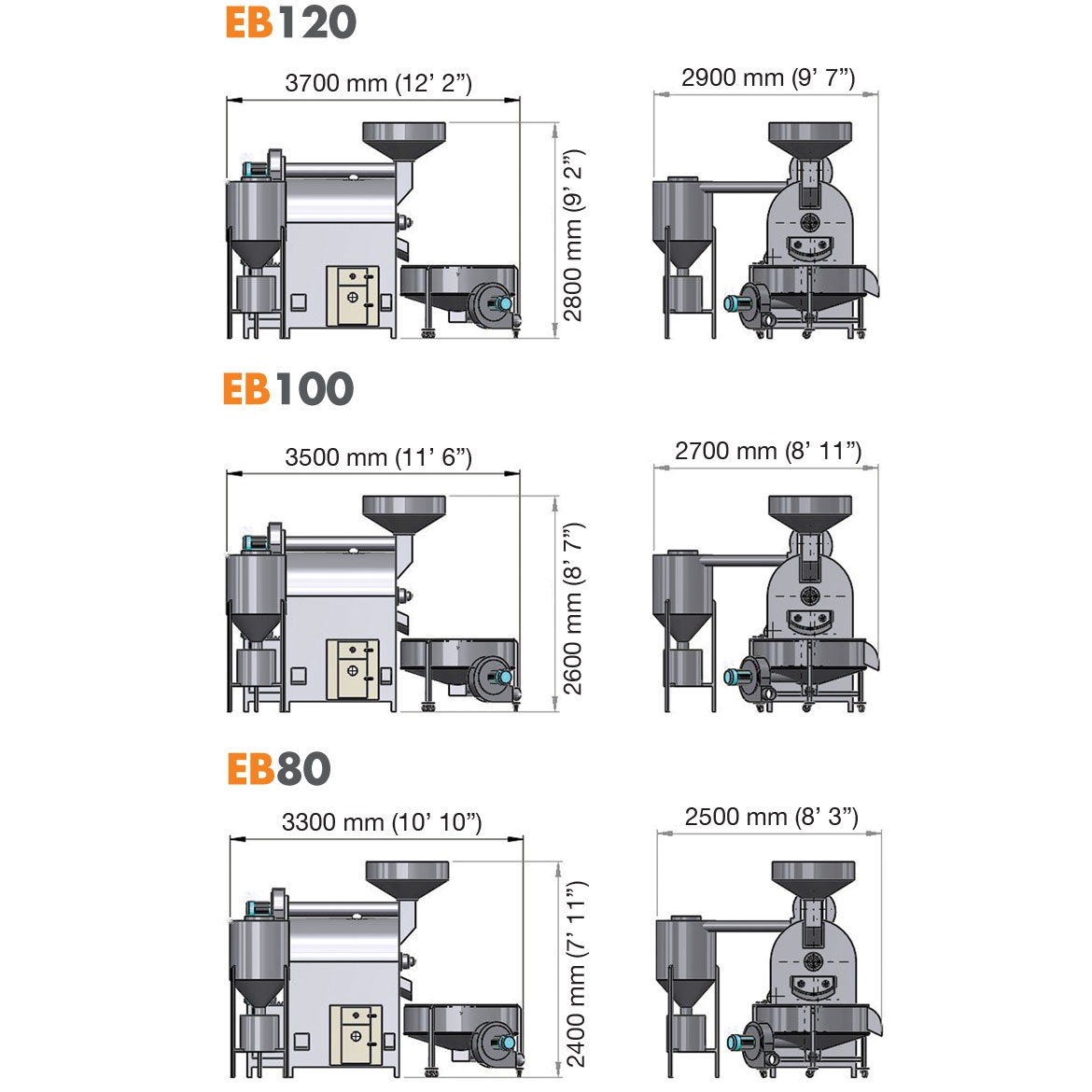

- EB80 120 kg/hour 260 lbs

- EB100 150 kg/hour 330 lbs

- EB120 180 kg/hour 390 lbs

- Total Electric Power 2,75 kW

- Maximum Thermal Power 100 kW

- Average Gas Consumption 4,5-12 Nm³/h

- Average LPG Consumption 3,5-9 kg/h

- Average Diesel Consumption 3,57-6,7 lt/h

- Total Electric Power 2,33 kW

- Maximum Thermal Power 80 kW

- Average Gas Consumption 4,5-9 Nm³/h

- Average LPG Consumption 3,5-7,5 kg/h

- Average Diesel Consumption 3,57-6,7 lt/h

- Sample Spoon.

You can control the roasted product with the sample spoon - Cleaning.

Proper machine cleaning can be done by auxiliary drawers - Heat Control.

The heat in the burner, air heat in chambers and product heat can be controlled by this unique design. - Piston.

Capability of fast discharge without manpower need. - Twister arm.

Sensetive sieving and long term use of the sieve with the teister arm adjustment. - Heat circulation system.

90% efficiency is provided with the special design of combustion system - Sieve.

Special design, to cool and seperate the salt from the roasted product. - Product discharge.

With this folding lid, product discharge has never been so easy.

Technology in a single key

Nuts Roasting Machines operation is quite easy with friendly touch screen panels. End of the day production and operator reporting can be added in software optionally. Maintance is more easy with online connection to PLC

Optional Solutions…

All software programs are written bu Sevval Makine engineers. According to special needs of the customeri, additionals can be done.

Is Salting Automatic?

With automatic salting, without depending on the standart capasity production of man power, the product is easily and undamaged salted.

Is Salting Manual?

The salting process is done without damage to the product and loss of space in production line

Roasted Products to Sags or Silo?

For minimum time loss and maximum production volume, automated elevator and silo solutions

Do you want to make final check?

You can make final check of your products at ergonomic and hygenic automated selection belt systems